In the past I had a lot of difficulty finding a reasonably priced backplanes and card cages for EXORbus systems and ended up trying to make my own. Since then, I have discovered many more PLC manufacturers that made EXORbus based systems and have been able to find more reasonably priced processor cards, backplanes, and cages. As a result, I did not find it necessary to make a new run of my Multi-Plane ExorBus backplanes. Instead, I am going to finalize and open source the design so that others can have it manufactured if they want.

Almost a year ago, I saw a Semy Engineering cage and backplane on sale for about $150. They typically are listed for over $500, but like much of this EXORbus hardware, it sits for sale for a long time, awaiting the perfect buyer who has a malfunctioning PLC system and a silicon wafer production line waiting on it to get repaired. As more and more of it reaches end-of-life, it accumulates on ebay until there is a glut, and finally the prices are slashed. While the price still isn't cheap, it is probably a better deal than trying to make one myself... or so I thought.

Unfortunately, when it arrived, I realized that it did not have a ±12V power supply for the RS-232 line drivers on my boards, only the +5V main power supply. This probably isn't too big of a deal, as most modern equipment deals well with lower RS-232 voltages and I am not planning on running very long serial communication lines. However, I felt like it was worth the time to get this running the right way. So, the hunt for suitable power supplies began.

±12V Options

Searching for a ±12V PSU is pretty difficult, as there is not a widely used term to describe them, and the minus sign usually gets ignored by the search or acts as a NOT operator. "Dual rail" led me to some decent options, and the electronics parts suppler search filters were helpful to find some (expensive) power supplies too. The MEAN WELL PD-2512 is a well-priced option, but it is quite large, and I dont need nearly that much power.

Parallel 12V PSUs

Apparently, you can connect two 12V switch mode power supplies so that the negative wire of one is connected to the positive terminal of the other (creating a GND reference), and leaving you with +12V, GND, and -12V power. While I understand how you could do this with two transformers to effectively create a single center-tapped transformer, I am struggling to wrap my head around how this would work properly with the various diodes and voltage regulators that might be involved in the full power supply. I believe a single 24V power supply with a "virtual center tap" GND reference using a couple of resistors would work as well to give ±12V, rather than just +24V. I am not excited about either of these options and I am not willing to risk my boards if this does not work properly.

MULTI-PLANE

While attempting to solve the ±12V issue, I noticed that my Multi-Plane backplane fit perfectly into the card slot, as was intended (whew)! The Multi-Plane was designed to be an ATX power supply injector for another backplane just like this. However, when I designed the board there really wansn't enough space to include the ATX power connector in a location that would allow to clear the sides of a card cage and clear the cards inserted into the board at the same time. So, To get it to work in this cage, I would need to swap the right angle ATX PSU connector with a straight one (or cut a hole in the side of the cage), but then I would lose a slot, I would still need an external ATX power supply, and I would not be able to use the MULTI-PLANE for anything else. This really isn't a great solution for me, just to get ±12V power.

DVD Universal PSU

In the end, I stumbled across an "EVD/DVD Universal Switching Power Supply Module" that is very cheap (<$6 shipped), widely available, and provides the ±12V at a reasonable 200mA for each rail.

It also includes ±5V power, useful to run cards with old DRAM chips. I will likely be using the +5V for a power indicator light or maybe connect to a relay to turn on the main power supply. I would not want to use this product to run the entire system though, and will be keeping the orignial power supply for that duty.Installation

The DVD power supply has a 7 pin XH (2.54mm pitch) header for the output power and a 3 pin CH (3.96mm pitch) header for the AC input and another for the switch. I went ahead and bought a pre-made pigtail for the XH header ("JST XH 2.54 2~12 Pin Connector Plug Single Head With 300MM Wire") and rearranged the wires so that the voltages would correspond with the wire colors, just like an ATX power supply.

A used two of the existing holes in the case to mount a couple of nylon posts for the new power supply board. One required a new hole in power supply PCB but fortunately it landed on the ground plane. I glued two more nylon posts onto the case, aligned with existing holes in the power supply board. I rigged up a splitter/extension harness to give the board 120V AC power from the plug socket. I also needed to add a jumper wire for the switch socket so that it will remain powered on. This case does not have a power switch on it, but I expect to add one to a front panel once I get it built.

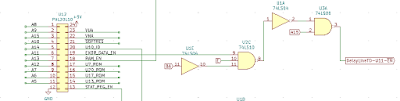

Next, I removed the backplane and soldered up the pigtail for the DVD power supply to the appropriate pins and ground plane. I also soldered up some wire to ensure that every slot gets the 12V power.

I routed the pigtail (covered in a piece of wire loom for protection and tidiness) under the backplane and card slots, out the side of the case, and back in one of the air holes to the DVD power supply.After a bit of testing to make sure the voltages looked correct, I plugged in an expendable board and was happy to see everything working!

Now I can start building up a usable OS-9 system that I won't have to tear-down every time I want to do some experiments with another board.